Сушка → Улавливание пыли → Просеивание

Сушка:

Влажный песок из бункера подаётся через тарельчатый питатель и ленточный конвейер во вращающуюся сушилку, где происходит сушка под воздействием горячих газов из топочной камеры.

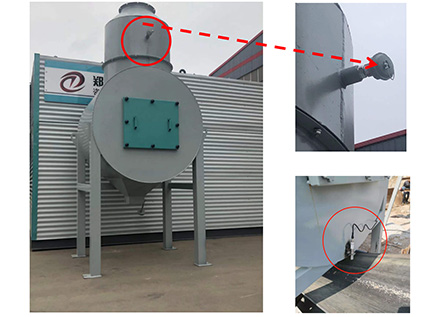

Улавливание пыли:

Пыль, образующаяся в процессе сушки, улавливается системой аспирации и циклонным пылеуловителем, после чего осаждается на ленточный конвейер сухого песка. Высушенный песок затем подаётся на линейное вибросито для просеивания.

Просеивание:

Сухой песок транспортируется ленточным конвейером на вибросито, где разделяется на фракции различного размера в соответствии с требованиями заказчика.

E-mail :

info@tongdingmachinery.comМатериалы отправляются в складской бункер ленточным конвейером или ковшовым элеватором, затем транспортируются из силоса материала на ленточный конвейер дисковым питателем, ленточный конвейер переносит материалы в загрузочную трубу. Градиент новейшей энергосберегающей загрузочной трубы должен быть больше угла кратера материала, чтобы материалы успешно попадали в сушилку. Барабан сушилки представляет собой вращающийся барабан, который находится под небольшим углом к горизонтальной линии. Материалы попадают в сушилку с одной стороны, теплоноситель следует в то же время. Через внутренний цилиндр, средний цилиндр, внешний цилиндр поступают в разгрузочное отверстие, наконец, попадают в разгрузочный бункер. После того, как теплоноситель проходит через сушилку, материалы, переносимые в тепле, нуждаются в циклонном пылеуловителе для улавливания. Если необходимо дополнительно снизить содержание пыли, он должен пройти через рукавный фильтр или мокрый пылеуловитель перед выгрузкой. Наконец, линейный вибрационный грохот отделяет готовые качественные продукты от высушенного материала.

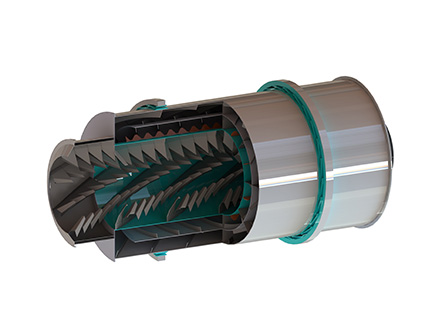

Принцип работы

Трехпроходная роторная сушилка имеет 3 зоны сушки в 3 цилиндрах (внутренний, средний и внешний), которые образуют вращающийся корпус. Тепловая обработка продукта с высоким содержанием влаги эффективно выполняется в этих 3 зонах сушки. Продукт подается из входного отверстия бункера, отправляется во внутренний цилиндр, где нагревание продукта происходит путем дальнейшего испарения влаги. Твердая составляющая продукта постепенно разбивается на куски и выгружается из выходного отверстия через третью конечную зону сушки. Горячий воздух, полученный в печи, отправляется во внутренний цилиндр, проходит через средний и внешний цилиндры. Затем горячий воздух отправляется в циклон, где удаляется пыль.

Формовочный песок, кварцевый песок, гранатовый песок, наждак, куала-кангсар, песок, речной песок, морской песок.

Песок для производства

Стеклянный песок

Железный порошок

Кварцевый песок

Титановый порошок

Песок машинного производства

Шлак

Каменный порошок

Речной песок

| Модель | HG2240 | HG2958 | HG3270 | HG3890 | HG4512 |

| Габаритные размеры (м) | 2.2x4 | 2.9x5.8 | 3.2x7 | 3.8x9 | 4.5x12 |

| Объем (м³) | 9.1 | 23.8 | 35.4 | 65.3 | 125.6 |

| Упрощенная форма: Частота вращения (об/мин) | 8-10 | 6-8 | 6-8 | 4-6 | 4-6 |

| Мощность (кВт) | 7.5 | 22 | 44 | 60 | 75 |

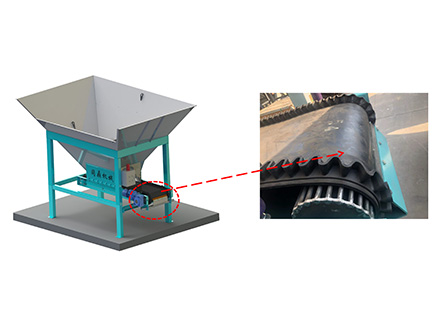

Хранение влажных материалов.

Специальная конструкция силоса, исключающая остаточный материал в четырех углах. Оснащен ленточным питателем.

Транспортирует материалы.

Высокая термостойкость. Влагостойкость. Стойкость к истиранию.

Программируемый логический контроллер, трансформатор зажигания, серводвигатель, реле давления ветра, реле давления потока и магнитный клапан.

Обеспечить теплом сушилку. Внутренняя часть выполнена из огнеупорного кирпича.

Полностью высушите влажные материалы.

Высокая износостойкость. Расширьте беговую ленту, чтобы повысить устойчивость и продлить срок службы. Экскурсия беговой ленты с применением нашей запатентованной технологии. Водяной бак под рамой, снижающий нагрев и противостоящий скольжению.

Уменьшите потери воздуха в системе принудительной подачи воздуха и увеличьте выход сушки. Точно отслеживайте и контролируйте температуру материалов и эффективно используйте тепло.

Более эффективно собирать пыль.

Отделение примесей, таких как почва в готовом песке.

Транспортировать материалы.

Высокая термостойкость. Влагостойкость. Устойчивость к истиранию.

Просеивание материала до разных размеров.

Установка специального двигателя (экспортно-ориентированного двигателя) с завода двигателей Xinxiang. Эффективное просеивание квалифицированных материалов.

Не стесняйтесь Обращаться К Нам За Лучшей Помощью и Обслуживанием

E-mail :

info@tongdingmachinery.comТелефон / Whatsapp / Wechat :

+86 13673306161Факс:

+86 0371 63715718Copyright © Zhengzhou TONGDING Machinery&Equipment Co., Ltd.Power by yisainuo